CUSTOMER-CENTRIC SOLUTIONS

Modine partners with our customers to provide solutions for a wide range of applications. We help customers across industries solve complex problems to ensure their climate solutions and performance technologies work more efficiently, last longer and add comfort to people’s lives. We pride ourselves on our nimble life cycle approach to problem-solving and our ability to anticipate and prepare for changing regulations, trends and demands.

Innovative Product Design

Modine is uniquely positioned to meet our customers’ growing demands for clean technology. In a rapidly changing world and regulatory environment, we value being nimble, adaptable and ahead of the curve. We provide customers with a sense of stability in the wake of rapid change by consistently offering solutions that perform, persist and improve. Our innovations encourage water conservation, an increased quality of life, a more climate-resilient society and more.

Performance Technologies

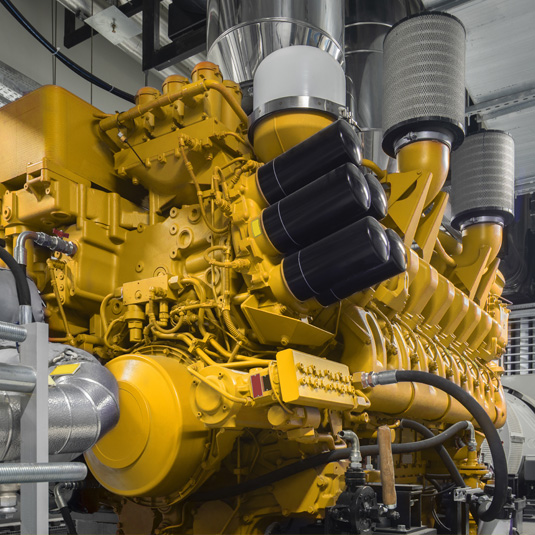

At Modine, our Air-Cooled Applications vertical uses the ambient air to solve the thermal challenges in ever-more efficient applications.

We help address our customers’ climate change concerns and ensure their critical systems stay running in harsh conditions. With these conditions becoming more present and governments tightening regulations, our focus on increased fuel efficiency and lower emissions support a cleaner, healthier world both on and off the road.

Energy Efficiency: Our Commitment

Fuel efficiency is an continuous challenge our customers face on a wide range of applications. Many of our customers’ solutions to this issue generate increased thermal demand. Thus, cooling the powertrain is key to their success. We have developed a number of technologies to solve these challenges.

For example, our customers have shifted toward smaller displacement engines paired with a turbo-charger to address fuel efficiency. For maximum power combined with this efficiency, our air-cooled charge air coolers dissipate the heat generated by the compression of the air in the turbo before it enters the engine. This provides optimal conditions for engine performance with the advantage of the compressed air.

On these coolers as well as all of our air-cooled products, we continue to focus on performance density by developing shallower cores with improved heat rejection. We are always striving for lighter weight products to contribute to the overall fuel economy of the system while not compromising the thermal performance.

Protecting Critical Systems: Our Commitment

As the environmental conditions continue get more extreme, back-up power becomes more important for essential operations. Our genset cooling modules keep critical gensets running in these extreme environments safeguarding healthcare facilities, data centers, and services in remote locations. In some of the most critical moments, our products support keeping the lights on.

Our genset modules cool the air and the coolant feeding into the engine to ensure optimal generator performance. With these optimal conditions, the genset consumes less fuel and is not at risk of over-heating. Thus, our modules are a critical component of the system as they protect the system from the risk of failing in these harsh conditions.

At Modine, our Liquid-Cooled Applications vertical develops thermal solutions for more efficient systems to address climate change concerns and meet new government regulations.

Given the demands of increasingly more efficient systems and space limitations on these systems, we partner with our customers to develop cost-effective, integrated solutions that increase fuel economy, lower emissions, and support the journey to electrification.

Climate Change: Our Commitment

With the transition to electric vehicles rapidly taking place for commercial and personal vehicles, there remains a critical need to “bridge the gap” by supporting advancing regulations and customer goals around reduced emissions in internal combustion engines. Modine’s stainless steel exhaust gas recirculation coolers (EGR-C) play a critical role in reducing emissions of nitric oxides (NOx), significant greenhouse gases and improving fuel economy by improved combustion.

For the last 30 years, Modine’s EGR-C technologies have been a leader in facilitating cleaner, healthier air by mitigating the release of greenhouse gas emissions and pollutants such as NOx into the atmosphere. In 1998, Modine was one of the first heat transfer manufacturers to market a heavy-duty truck EGR-C, followed by a light-duty automotive EGR-C in 2001. With decades of global expertise, we can offer an integrated system approach to reduce emissions and optimize engine performance through the application of EGR-Cs.

Our EGR-C products cool a turbocharged engine’s exhaust gas with coolant, returning the cooled exhaust gas back to the engine’s intake air to reduce combustion temperatures that produce NOx. Use of Modine’s EGR-C components and systems helps customers mitigate the potential air quality impact of their products.

Energy Efficiency: Our Commitment

As government regulations continue to push for stricter fuel efficiency, the need for solutions that can most effectively cool these applications increases. We have developed liquid cooled solutions with improved performance density, higher performance with smaller coolers. These technologies play a vital role in supporting our customers in regulatory compliance and environmental responsibility.

Our layered core oil coolers keep transmission temperatures in an optimal range by ensuring that the oil lubricating the system is cooled. By keeping these temperatures low, the system operates more efficiently and thus consumes less fuel.

We also offer liquid charge air coolers as a solution to eliminate the excess heat from the turbocharger compressing the combustion air. This ensures that the compressed air is cooled before entering the engine which creates the optimal environment for maximum power and fuel efficiency.

At Modine, our Advanced Solutions Vertical develops systems and solutions to improve air quality and conserve natural resources.

Our thermal management systems and components are in all types of electric vehicles, helping to eliminate harmful emissions from automobiles and commercial vehicles. Our Coatings solutions protect systems from corrosion, extending the life and saving space in landfills across the globe.

Zero Emission Mobility: Our Commitment

As the transition to electric vehicles continues, safety and range are two primary considerations. Regulating the temperature of the battery pack and power electronics in the vehicle is critical for optimal performance and increased range on a single charge, while ensuring safe operation.

Our EVantage™ Battery Thermal Management System (BTMS) gives customers full control of battery temperature in all environments, from hot summer afternoons to icy winter mornings to ensure optimal battery performance.

Our EVantage Electronics Cooling Package (ECP) keeps the traction motor and power electronics cool for all loads for most efficient vehicle operation.

Protecting Resources : Our Commitment

Deterioration of HVAC/R equipment resulting from corrosion has long been an issue in the harshest environments, such as wastewater treatment facilities, oceanfront and marine locations. This leads to the breakdown of critical systems, an increase in landfill waste, and ultimately replacement of the HVAC/R system which contributes to more unnecessary resources. As development continues in oceanfront cities and towns across the globe, our Coatings solutions are there to prevent this corrosion from the start.

Our ElectroFin® e-coat gives superior corrosion protection of OEM HVAC/R equipment with over 25 years of field installations in the harshest environments. ElectroFin extends the useful service life of equipment in corrosive environments and provides systems the ability to perform at peak energy efficiency for many years as compared to unprotected equipment in the same environment. By extending the useful life of systems protected with ElectroFin coating we ultimately reduce landfill space resulting from premature equipment replacement.

Our InSitu® spray-applied, environmentally-friendly coating is a water-based product used in aftermarket applications to protect HVAC/R equipment. InSitu coating extends the life of equipment and can be applied in our factory or at one of our trained licensees to minimize logistics costs to the installation site.

Climate Solutions

Our Heat Transfer Products vertical designs, manufactures, and tests heat transfer products for a variety of applications and markets.

These products promote the use of sustainable refrigerants, allowing us to partner with our customers to engineer a cleaner, safer world.

Coil Design: Our Commitment

The coils designed and manufactured by Heat Transfer Products are designed to meet the durability and performance requirements of customers within HVAC&R, Power, and Process markets.

Simply put, when heat exchangers leak, there are environmental impacts. Whatever fluid that was in the heat exchange system now has the ability to escape. This can result in increased water usage in hydronic applications, or ozone impacts if the fluid is a GWP refrigerant. By choosing the right materials & design, our coils stand up to the environment and application they are placed into.

Additionally, proper coil design can minimize the energy used in an application. In designing coils that maximize surface area and allow the temperature potential of the fluid to transfer to outside the coil, we help our customers create the most efficient and least environmentally impactful solutions.

Our engineers work hand-in-hand with our customers so that the coils designed for their application strike the right balance between efficiency & durability to strive for the best environmental outcome.

Environmental Management: Our Commitment

Within Heat Transfer Products, we are committed to actively managing our operational carbon footprint. We continue to make strides in deepening our understanding of our impact by tracking KPIs related to our emissions and energy use. These KPIs allow us to track progress, but also deepen our understanding of opportunities for impact.

Projects in our plants are prioritized to reduce our environmental impact. For instance, our manufacturing facility in Guadalajara, Spain upgraded 100% of its lighting to LED bulbs in 2019. Since then, the plant has saved approximately 85,000 kWh of energy each year, equivalent to 60.2 metric tons of CO2e.

In addition to plant-related improvements, we also actively manage our supply chain, building and maintaining partnerships that help reduce emissions. By identifying ways to optimize transportation & logistics, or sharing best practices to reduce carbon footprint impact, we are committed to actively managing our environmental impact.

At Modine, we strongly believe that HVAC&R manufacturers must play a responsible role in an era where sustainability is key to the preservation of our planet.

We provide a wide array of solutions to the HVAC&R market that help enable positive environmental impact. Whether it be providing clean air to classrooms, efficiently conditioning indoor spaces, or driving away from high-GWP refrigerants, the HVAC&R vertical strives to engineer a cleaner, healthier world.

Providing Clean Air: Our Commitment

The COVID19 pandemic highlighted the need for proper ventilation, bringing fresh, clean air to indoor spaces. Our Single Packaged Vertical Units (SPVUs) have been doing just that for classrooms for the past 25 years.

Our ClassMate® SPVU unit heats, cools, and filters outside air, allowing students and teachers to stay healthy and focus on learning. Additional options including energy recovery wheels, economizers, and control systems ensure that the unit runs as efficiently as possible. By providing single-zone clean air to classrooms, this product prevents particles from moving from classroom to classroom when compared to centrally installed return air systems.

Energy Efficiency: Our Commitment

For years, the typical solution for heating a commercial greenhouse was an 80% efficient gas-fired unit heater. Operating at up to 97% thermal efficiency, Modine’s Effinity™ condensing unit heater features the highest efficiency available in North America for commercial and industrial gas-fired unit heaters, which will dramatically lower energy costs and CO2 emissions. In addition, Modine has launched the Effinity™ Payback Calculator, which provides customers location-specific calculations of not only how much money they can save in operating costs, but what their environmental impact over using a standard efficiency product would be.

Refrigerants: Our Commitment

The unique properties of refrigerant gases mean they can absorb and reject heat easily and therefore be used to provide temperature management, not just for people, but for equipment that help the world function.

That said, many refrigerants are greenhouse gases that, if released into the atmosphere, contribute towards global warming. Refrigerant phase-down legislation, like the European F-Gas protocol, is something we agree wholeheartedly with and have taken a proactive stance towards.

Our CO2 gas coolers enable supermarkets to utilize low-GWP refrigerants in their refrigeration systems, transitioning away from R410a and R134a.

At Airedale by Modine, we passionately believe that air conditioning manufacturers must play a responsible role in an era where sustainability is key to the preservation of our planet.

Air conditioning as an industry rightfully comes under pressure due to the refrigerant gases we use in our products and the energy they consume during their operational life. There are life-saving and game-changing technologies in our day-to-day lives that require refrigeration and air conditioning to enable them to function properly, for example, hospital and laboratory equipment, and data centers. The world relies on air conditioning more than we realize.

Refrigerants: Our Commitment

The unique properties of refrigerant gases mean they can absorb and reject heat easily and therefore be used to provide temperature management, not just for people, but for equipment that help the world function.

That said, many refrigerants are greenhouse gases that, if released into the atmosphere, contribute towards global warming. Refrigerant phase-down legislation, like the European F-Gas protocol, is something we agree wholeheartedly with and have taken a proactive stance towards.

We take our environmental responsibilities seriously. For several years we have focused a large proportion our R&D resource on moving towards suitable replacements for refrigerants gases such as R410a and R134a. This development work started before the current F-gas regulations were introduced and started forcing the wider industry’s hand. This has helped create a level playing field in some respects but also helps us as a proactive business stay one step ahead.

Energy Efficiency: Our Commitment

At Airedale, we believe that energy efficiency should be driven, not by legislation, but by a genuine will to reduce air conditioning’s cost to our customers and the environment. Energy efficiency is one of three core pillars that make up our R&D ethos, along with the environment and the deployment of leading edge technology.

Building energy efficiency into product design is one thing, but intelligent system design can also help end-users maximize efficiencies and reduce running costs. For example, Airedale has been a pioneer of free cooling technology on its chiller products and introduced this energy-saving technology over 18 years ago. Most chillers at the time were supplying chilled water at 6/12°C whereas Airedale increased these to maximize free cooling and enhance energy efficiency. Our data center solutions are designed to operate in free cooling mode for up to 98% of the year in many regions, delivering huge energy savings.

Airedale also provide intelligent controls solutions that allow HVAC equipment to flex with their environment, creating optimized operating conditions that save energy while maintaining performance.

By saving energy and water and only using low GWP refrigerants in our cooling solutions, we help our clients solve some of the biggest challenges the world is facing as we move to a digitized, decarbonized and urbanized future.

Regulations and Compliance

We work toward our purpose by being innovators who have a firm grasp on emerging industry trends. We also stay abreast of environmental laws and regulations through the work of our Legal and Compliance teams. Many of our associates are active participants within industry trade associations and organizations that monitor regulatory trends and developments such as the Air-Conditioning, Heating and Refrigeration Institute (AHRI) and the American Society of Heating Refrigeration and Airconditioning Engineers (ASHRAE).

Supply Chain Management

Modine utilizes a thorough evaluation process to approve suppliers. We require companies to submit a self-assessment designed to provide details on how a new supplier can meet each of our commercial, quality, environmental and logistics requirements. When screening suppliers, we also appreciate and take into consideration numerous factors, such as the presence of Environmental Management System practices and policies as specified under ISO 14001, as well as policies on supplier diversity and health and safety management.

Life Cycle Approach

We work closely with our customers to assess their entire system to ensure our products integrate well with other components. This systems-based approach helps us consistently provide the best possible thermal solutions for our customers. We look at every aspect of the product design, from raw materials to end-of-life recyclability, optimizing total cost of ownership for our customers and reducing negative impacts across the product life cycle. This high-level approach allows us to customize solutions and enable our customers to meet their own sustainability goals and milestones.

We Anticipate and Prepare for Change

We offer our customers the flexibility to stay ahead of new and emerging regulations while fulfilling the growing demand for sustainable technologies. In response to increasingly stringent emissions, fuel economy and energy efficiency standards, our customers require products and systems that are lighter weight, more compact, more efficient and more durable than ever before. We provide customizable solutions that can meet these evolving needs to help customers achieve their sustainability goals.